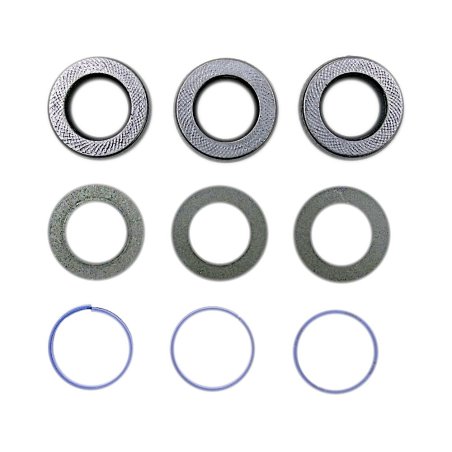

The original Kränzle Junior 120 pump seal kit is a set of service parts designed to restore tightness of the pump section. Used during pump refurbishment when worn seals cause leaks, pressure fluctuations, or reduced performance.

MPN / reference: 43.098

Weight: 0.060 kg

Dimensions / size (packaging): 10×1×10

APPLICATION

Used in typical service work on pressure washer pumps, including:

- replacing seals in the pump working section during repair or inspection,

- eliminating leaks around the pump head / plunger section,

- refurbishing the pump in an older Junior 120 unit after intensive use,

- service work after long periods of downtime (when seals lose tightness).

SYMPTOMS - WHEN IT’S WORTH REPLACING

Common symptoms indicating pump seals should be replaced:

- water leaks around the pump or under the unit,

- drop in working pressure despite functional accessories,

- jet pulsation and unstable pump operation,

- difficulty maintaining constant pressure during washing,

- moisture/leak marks visible after downtime.

HOW TO CHOOSE THE RIGHT PART

To avoid selection mistakes, follow the manufacturer data and compare with removed parts:

- by manufacturer MPN / reference: 43.098,

- by machine match: kit described for Kränzle Junior 120,

- by comparison with the removed set: verify profiles and quantities before installation.

Accurate fit is critical - an incorrect seal set can cause leakage and rapid wear.

COMPATIBILITY

Kit described as intended for the Kränzle Junior 120 pump (older model).

For safe selection, confirm compatibility by MPN 43.098 and the pump documentation/parts list for your specific pump variant.

[faq]

Will this kit fit every Kränzle Junior 120 unit?|In most cases yes, but older units may have production variants. The safest method is to confirm by MPN 43.098 and the pump parts list.

Does a pressure drop always mean the pump seals are worn?|Not always. Similar symptoms can be caused by the nozzle, valves, air ingress, or water supply issues. However, if leaks around the pump and pulsation are present, seals are one of the first diagnostic points.

Can I use an aftermarket alternative instead of the original kit?|Only if dimensions and profiles match exactly and it’s rated for high-pressure systems. In practice, to reduce leakage risk, selecting by MPN and manufacturer documentation is the safest approach.

[/faq]